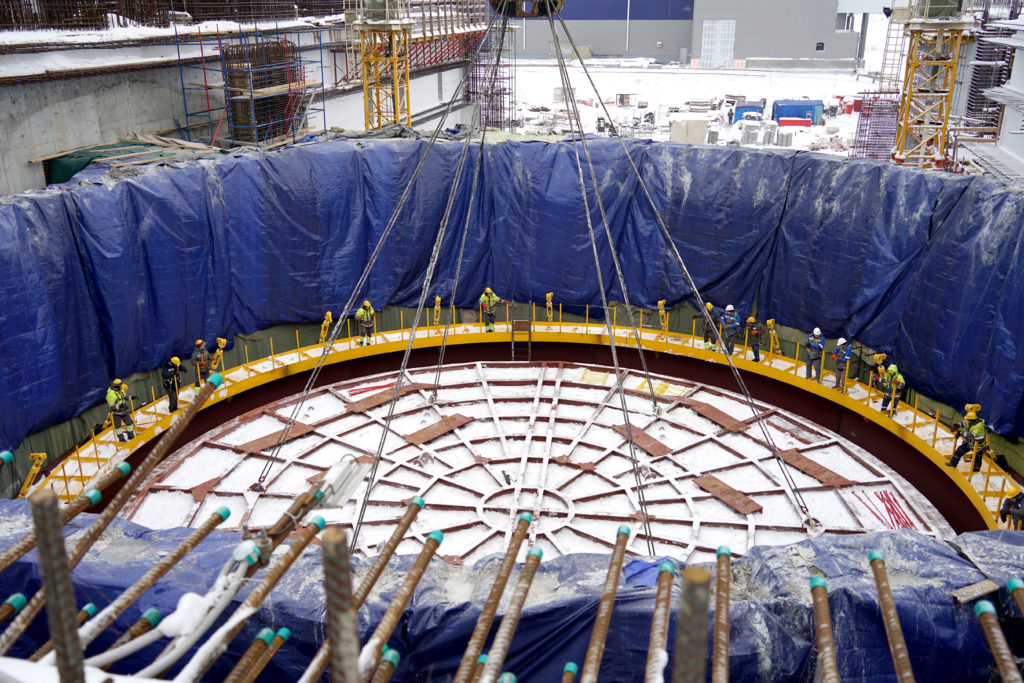

Rosatom has achieved a landmark milestone in construction of a power unit with the innovative fast neutron BREST-OD-300 reactor on the site of the Pilot demonstration energy complex (PDEC) in Seversk, Tomsk Region (West Siberia).

The steel reactor baseplate with the total weight of 165 tons has been installed. The workers have also loaded into the reactor shaft the first part of the reactor vessel – the lower tier of the containment.

The containment structure is the outer part of the reactor vessel. It provides retention of heat-insulating concrete, forming an additional localizing barrier of protection, which surrounds the boundary of the coolant circuit. On its surface, the temperature should not exceed 60 degrees Celsius, and the radiation background is actually equal to the natural background.

A 300 MW NPP powered by the lead-cooled BREST-OD-300 fast reactor, based on the principles of “natural safety”, is the key element of the Pilot demonstration energy complex, which is under construction on the site of the Siberian Chemical Combine in Seversk, an enterprise of TVEL Fuel Company of Rosatom. The PDEC facilities are developed under Rosatom’s strategic “Proryv” project (“the Breakthrough”). In addition to the power unit, it also includes facilities of the on-site closed nuclear fuel cycle – a unit for the fabrication of uranium-plutonium nitride fuel, as well as a unit for reprocessing of irradiated fuel.

“We have started installation of the world’s first lead-cooled fast reactor, the fourth generation reactor BREST-OD-300. Unlike traditional light-water VVER thermal reactors, BREST has an integral layout. Its vessel is not an all-metal structure like the VVER, but a metal-concrete structure with metal cavities to accommodate the primary circuit equipment. The space between the cavities should be gradually filled with concrete filler during construction. In addition, the BREST vessel is larger in size, it can be delivered only in parts, and the final assembly is possible only at the PDEC construction site,” commented Vadim Lemekhov, Chief Designer of the BREST-OD-300 reactor unit and General Designer of the “Breakthrough” project team.

Reference

The advantage of fast reactors is their ability to efficiently use the fuel cycle’s secondary byproducts (in particular, plutonium) for energy production. At the same time as having a high regeneration factor, fast reactors can produce more potential fuel than they consume and also burn out (i.e. use in the process of energy generation) highly active transuranic elements (actinides). The design of the BREST-OD-300 lead-cooled reactor is based on the principles of so-called natural safety. The features of the reactor made it possible to abandon the melt trap, a large volume of support systems, and also to lower the safety class of the non-reactor equipment. The integral design and physics of the reactor facility make enable to exclude accidents requiring evacuation of the population. In the future, such installations should not only enhance the safety of nuclear power, but also make it more economically competitive in comparison with the most efficient thermal power generation (in particular, steam-gas technology).

The BREST-OD-300 reactor will provide itself with its main energy component – plutonium-239 – reproducing it from the isotope uranium-238, which has a relative abundance of more than 99% (it is the isotope uranium-235, which makes about 0.7% of natural uranium, that is currently used to produce energy in thermal reactors). The introduction of such technologies will increase exponentially the efficiency of natural uranium. Uranium has about a 86% share in the world reserves of energy resources, compared to coal at 8%, oil at 3%, and gas at 3%.

TVEL Fuel Company is the nuclear fuel division of Rosatom. It incorporates enterprises for the fabrication of nuclear fuel, conversion and enrichment of uranium, manufacturing of gas centrifuges, as well as research and design organizations. It is the sole supplier of nuclear fuel for Russian nuclear power plants. TVEL provides nuclear fuel for more than 70 power reactors in 15 countries, research reactors in eight countries, as well as transport reactors of the Russian nuclear fleet. Every sixth power reactor in the world operates on fuel manufactured by TVEL.

TVEL actively develops new non-nuclear businesses in chemistry, metallurgy, energy storage technologies, 3D printing, digital products, and decommissioning of nuclear facilities. Rosatom’s industry integrators for additive manufacturing and energy storage systems have been established within the TVEL Fuel Company corporate structure.