The Federal Service for Environmental, Technological and Nuclear Supervision (Rostechnadzor) has issued a license to Siberian Chemical Combine (an enterprise of Rosatom Nuclear Fuel Division in Seversk, Tomsk Region) to operate a nuclear installation of the Unit for fabrication and refabrication of dense nuclear fuel.

The Fabrication/Refabrication Unit is a facility of the Pilot Demonstration Energy Complex (PDEC), which is under construction in Seversk under the strategic “Proryv” (or “the Breakthrough”) project. PDEC is a cluster of nuclear technologies of the future, it includes three unique interconnected facilities: a unit for the production (fabrication/refabrication) of mixed uranium-plutonium nitride nuclear fuel, a power plant with an innovative generation IV fast neutron reactor BREST-OD-300, and a unit for the reprocessing of irradiated fuel. Thus, for the first time in the global nuclear industry, a nuclear power plant with a fast reactor will function with an on-site closed nuclear fuel cycle.

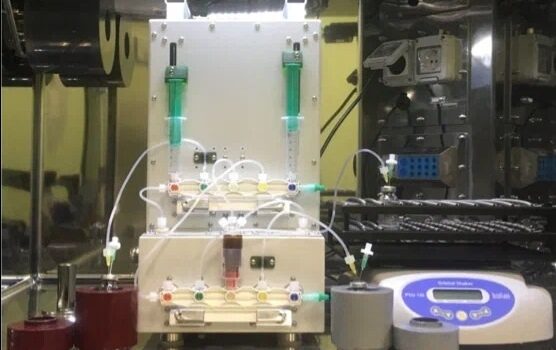

On March 25, 2024, during the international forum ATOMEXPO-2024 in Sochi, a test launch of the carbothermal fusion line at the fuel fabrication unit was started via a teleconference with Seversk. Obtaining the license issued by Rostekhnadzor enables to proceed to the next stage of equipment and technological modes testing. So far the current license conditions allow comprehensive testing of the equipment at all shop-floors of the complete chain of BREST-OD-300 fuel manufacturing using depleted uranium.

For the BREST-OD-300 fast reactor, Rosatom has developed innovative mixed dense uranium-plutonium nitride fuel (so-called MNUP fuel). It is based on two key components – depleted uranium, which is a by-product of uranium enrichment for nuclear reactors, and plutonium extracted from irradiated nuclear fuel. At the current stage, using depleted uranium does not carry any risks in terms of nuclear and radiation safety. This material consists almost entirely of the stable isotope uranium-238 with the content uranium-235 of about 0.1% (in natural uranium it is 0.7%, and in nuclear fuel for thermal reactors of NPPs – up to 5%). At the next stage, after obtaining the relevant Rostechnadzor authorization for plutonium handling, the equipment of the facility could be used to produce the final MNUP fuel of the BREST reactor core.

Reference

Production and introduction of MNUP-fuel will enable to expand the resource base of the nuclear power industry multifold, utilize depleted uranium stocks, reprocess irradiated fuel assemblies to produce fresh fuel instead of storage, and radically reduce volumes of nuclear waste and its activity.

Unlike classical nuclear fuel based on enriched uranium dioxide, MNUP fuel cannot be produced using standard technology and equipment. In addition to non-standard fuel matrix materials, using radioactive plutonium from spent nuclear fuel is also a key factor. To avoid irradiation of staff, manufacturing of uranium-plutonium fuel has to be fully automated, virtually unmanned. To produce MNUP fuel, the PDEC will use four manufacturing lines: a line for carbothermal synthesis, a line for production of MNUP fuel pellets (thus, the production of pellets will be accomplished in two stages), a line for assembling of fuel elements, and a line for the assembling of complete fuel cassettes. Currently, commissioning of the installed equipment is underway.

Within the closed nuclear fuel cycle implemented at PDEC, spent fuel from the BREST-OD-300 reactor will be sent for refabrication (i.e. re-manufacturing of fresh fuel) after reprocessing, thus, this system will gradually become almost autonomous and independent of external energy supplies, except for depleted uranium.

The advantage of fast neutron reactors is their possibility to efficiently use secondary products of the fuel cycle (in particular, plutonium) for energy generation. At the same time, having a high reproduction rate, fast reactors are able to produce more potential fuel than they consume, as well as after-burn highly active transuranic elements (actinides).

The BREST-OD-300 reactor will supply itself with the main energy component – plutonium-239, reproducing it from uranium-238 isotope, which is contained in natural uranium ore in excess of 99% (currently, uranium-235 is used for energy production in thermal reactors, the content of which in natural uranium ore is about 0.7%).