Rooppur NPP will operate with the most modern and efficient nuclear fuel developed specifically for generation III+ nuclear power units with VVER-1200. In the future, such fuel makes it possible to extend the NPP fuel campaign from 12 to 18 months. This is much more cost-effective and profitable as NPPs generate more electricity per year because fewer shutdowns are required to load fresh fuel into reactors.

Nuclear fuel is the youngest and most modern of all types of fuel used by humanity. The basis of the fuel is uranium. This element is inherently extremely energy efficient. One uranium pellet generates the energy equal to the energy generated by 1 ton of oil.

Natural uranium is produced from underground mines and open pits, or by the in-situ leaching. The ore is ground and dissolved to produce a concentrated uranium salt. The salt is dried and the dry concentrate is purified. After that, through the reaction of the resulting uranium oxides with fluorine, they get a special compound: uranium hexafluoride, which is then sent for enrichment. The peculiarity of uranium hexafluoride is that it remains solid at ordinary pressure and temperature, however, when heated, it can immediately transform into a gaseous state, skipping the liquid form. This property of uranium hexafluoride is used for enrichment of uranium-235 isotope, the initial content of which is low in natural uranium, only 0.7%.

At a special enrichment plant, uranium hexafluoride is first transformed from a solid to a gaseous state by heating, after that it is fed into gas centrifuges, where, due to the high rotation speed, a centrifugal force exceeds the gravitational force of the Earth by hundreds of thousands of times. Only uranium in the gaseous state can be enriched. In the course of this colossal rotation, heavy molecules of uranium-238 hexafluoride are separated from lighter molecules of uranium-235 hexafluoride (U235), while the amount of U235 grows to the required level. The fuel of NPP reactors is required to have up to 5% of a U235 content.

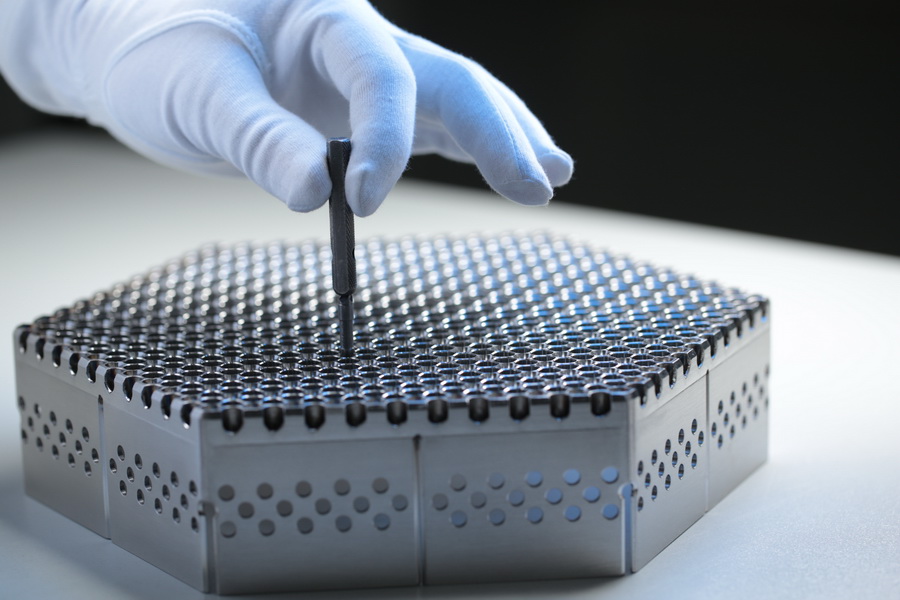

Enriched uranium is supplied to nuclear fuel fabrication plants, where it is converted into uranium dioxide, compressed and sintered into pellets. To make fuel elements uranium dioxide pellets with 5% uranium-235 enrichment are placed inside zirconium shells and sealed with plugs. Fuel elements are assembled into fuel assemblies (FA). Due to their rigidity, fuel assemblies remain in the reactor core for 5 years.

Fuel assemblies are those modules that are loaded into or unloaded from the reactor during the refueling. Fuel assemblies are delivered from the manufacturing plant to the nuclear power plant in special transport containers. Fresh nuclear fuel has a very low level of radioactivity that’s why it is safe from the radiation point of view.

NPPs use a special safety system to transport and store nuclear fuel at sites. All operations are carried out in a special building. Fuel assemblies in transport cases are placed on special platforms to be further delivered to the reactor compartment.

At a time 163 fuel assemblies are loaded into a VVER-1200. In the course of operation, part of the fuel assembly “burns up”, that is, it exhausts its service life, and a refueling is required to unload the burn-up fuel from and load fresh fuel into the reactor. The operation of a large nuclear power unit for a year requires only a few tens of tons of low-enriched uranium. By comparison, a coal-fired plant requires five trainloads of coal to generate a similar amount of electricity.

Rosatom has a full range of nuclear energy solutions, from NPP design and construction, including nuclear fuel supply, personnel training, plant operation, unit maintenance and repair, to decommissioning. Rosatom Fuel Company TVEL is one of the world’s largest manufacturers of nuclear fuel. 14 countries around the world use TVEL fuel at their NPPs, which means every 6th power reactor. Besides, foreign research reactors based on domestic technologies are also operated with TVEL fuel. TVEL comprises companies specializing in gas centrifuge production, uranium conversion and enrichment, nuclear fuel fabrication, as well as research and development organizations. Fuel assemblies with fuel developed specifically for generation 3+ nuclear power units with VVER-1200 are manufactured by two TVEL companies (in Elektrostal and Novosibirsk), which ensures additional reliability in supplies for new power units.