Rosatom develops technologies and solutions for green energy and carbon footprint reduction, including also solutions for the environmental well-being of Russia and the world.

At present, lithium is considered a critical component of energy storage systems, which have already become widespread in a number of high-tech industries. Lithium batteries are used in electronics, to ensure the operation of transport, uninterruptible power supply systems, and to make wind generators more effective in terms of electricity production. Rapid changes in the transport sector and on the electricity generation market where Rosatom operates brought about the business direction split-off in 2020 and further establishment of an integrator division – Energy Storage. The Division specializes in the manufacture of energy storage systems based on lithium-ion batteries (LIB) of various capacities and applications.

Lithium-ion batteries have a number of advantages over lead-acid, alkaline and other analogues, and ensure operational and economic efficiency for the customer. They have a longer service life, no “memory effect” and can be recharged at a convenient time, which reduces equipment downtime. Rust-proven electrode plates allow the development of various modular solutions. LIB storage systems are sealed, require neither maintenance nor a special room for recharging, which saves space and requires no personnel.

Rosatom’s lithium-ion solutions have the following applications:

- traction batteries for electric vehicles, specifically electric buses and trolleybuses, passenger electric vehicles, light commercial electric vehicles (LCVs), electric forklifts, railway transport, water transport;

- stationary energy storage systems, specifically electrical networks and generation, emergency and uninterruptible power supply systems, price-dependent consumption systems, storage systems for renewable energy sources, charging stations;

- traction batteries for special equipment, such as warehouse, cleaning, municipal, mining, airport equipment, robots, etc.

The introduced Rosatom’s products have made it possible to solve problems having consequences of various levels and criticality. In the case of energy supply to isolated areas, any generation sources are integrated into the network, including small and alternative ones. The energy system operates in automatic mode with the possibility of remote monitoring and control, which increases the energy efficiency of the facility, makes it possible to ensure the electricity generation-consumption balance, and significantly reduces fuel costs. Uninterruptible power supplies and operational direct current systems ensure instant switch to battery power in the event of a power failure and also auxiliary power backup for energy facilities.

The Division’s current manufacturing capacity is 150 MWh of batteries for stationary systems or about two thousand traction batteries for electric vehicles per year.

The Energy Storage Division has several manufacturing facilities.

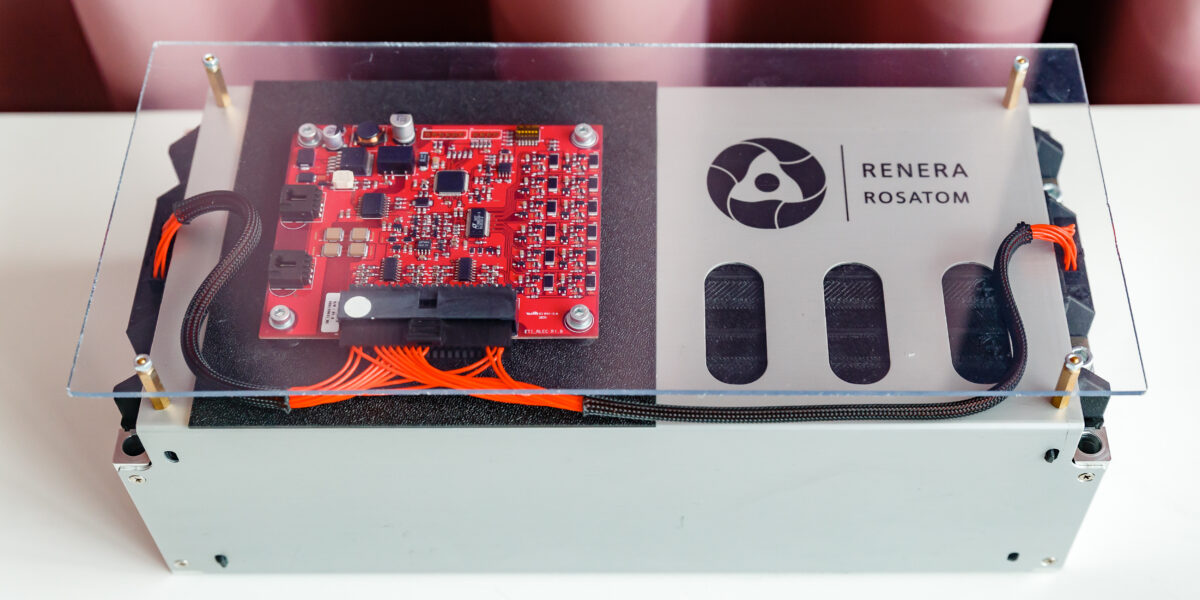

At the end of 2022, the industry integrator launched a new pilot production of energy storage systems at the site of the Moscow Polymetal Plant, where Rosatom specialists do R&D, manufacture and test prototypes of energy storage systems for trolleybuses with increased autonomous run, electric vehicles, operational direct current systems, uninterruptible power supplies.

In October 2022, Rosatom began construction of Russia’s first energy storage gigafactory in the Kaliningrad region. The largest-scale Russian company with a capacity of 4 GWh per year will meet the needs of domestic electric vehicle manufacturers for traction lithium-ion batteries, while the electrical grid facility will meet the needs for stationary energy storage systems. The first Russian gigafactory will start operating in 2025.

In 2023, for the first time in Russia, Rosatom and Mosgortrans signed a contract for the supply of more than 155 thousand traction batteries for electric vehicles, which envisages the creation of a second gigafactory for the production of energy storage systems in New Moscow (Krasnaya Pakhra village). The new manufacturing facility will start operating in 2026.

One of the projects was implemented at the ZiO-Podolsk plant of Rosatom Mechanical Engineering Division, where a 300 kWh intelligent energy storage system is successfully operated. The commercial dispatch using an intelligent energy storage system ensures optimized daily schedule of energy consumption, which helps reduce power costs. The storage device installed at the end consumer’s site supplies electricity to its internal grid during the hours of maximum cost of electricity and power. The intelligent part of the system provides predictive analytics related to the grid load and remotely controls the charge and discharge schedule of the “Commercial Dispatcher”. A special feature of the system is the constant improvement of algorithms based on machine learning methods.

In addition to the batteries manufacturing, Rosatom is also working on projects for their recycling. Rusatom Greenway JSC (Rosatom company, the industry environmental integrator in the field of management of hazard classes I-V of industrial and consumer waste) is creating an eco-technopark “Center” in the city of Dzerzhinsk, Nizhny Novgorod region. The company will process lithium-ion batteries of electric vehicles, railway vehicles, mobile devices and uninterruptible power supplies. The technological process is aimed at extracting useful material resources, which will further be used, among other things, in the production of new electric vehicle batteries. Ecotechnopark “Center” will be the first Russian project for a closed production cycle in the field of electric transport.

The activities of the industry integrator of Rosatom abroad are aimed at developing international sales, searching for stable partnerships and mutually beneficial scientific and technical cooperation.

The product offer on the international market includes both ready-made energy storage solutions and projects for localizing the production of batteries and energy storage systems in the countries of possible customers.

The Republic of Belarus acts as a strategic partner in the international projects. The projects that have been implemented in the field of traction batteries for electric vehicles since 2013 range from the supply of batteries for the first Belarusian electric vehicle to providing Rosatom solutions to Belarusian-made mining dump trucks and electric buses. In addition to Belarus, the Division is developing cooperation with other CIS countries. The cooperation geography also includes non-CIS countries – cooperation opportunities are being negotiated and discussed with companies in India, South Africa, Myanmar, Saudi Arabia, the UAE, Egypt, and Serbia.

Rosatom’s solutions will allow foreign countries that have no domestic competencies in the production of energy storage systems to make the transition to low-carbon energy, and also can contribute to the active introduction of renewable energy sources, increased reliability of energy systems, mass electrification of transport and increased level of technological development.