General Information

Composite materials are of great interest because they are non-corrosive, magnetically inert and do not lose their properties at ultra-low temperatures. Such materials can be used in both aerospace industry and in the production of consumer goods. The properties of composites make it possible for the manufacturers to build features right into their designs, so that they can increase product durability while reducing environmental impact.

The Russian market amounts to ~1% of the global market (~100 bln RUB by the end of 2022), but there is a constant growth of minimum 5% per year. Today the per capita consumption of composites in developed economies is 4–10 kg/person. The same indicator for Russia is less than 0.5 kg/person.

Russian composites market structure in 2022 (fibre / plastic), bln RUB:

- Carbon fibre (CF) — 2,103 / 35,208

- Glass fibre (GF) — 16,496 / 56,794

- Other fibre (basalt / aramid) — 4,629 / 9,020

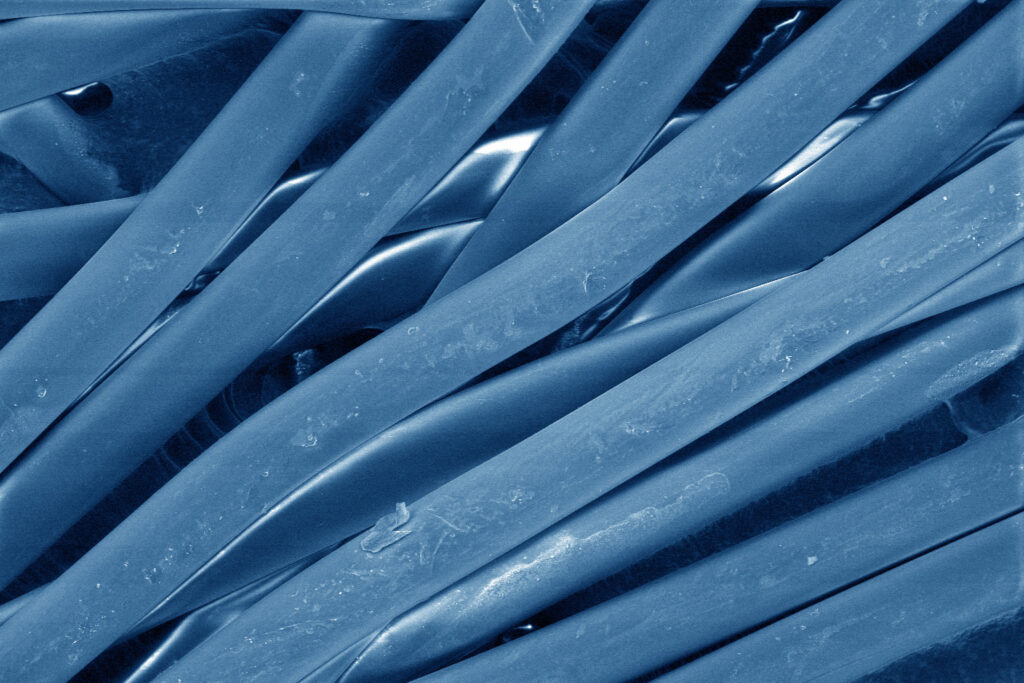

Glass is the key filler (average 60–70% in fibres/products), but carbon fibre is catching up fast: over the last few years the carbon fibre market has tripled from 300 tonnes to over 1,000 tonnes in 2023.

Russia’s largest producer of composites is Rosatom Composites Division, which has the capacity to produce both raw materials and finished goods.

The Division has the only state-of-the-art carbon fibre plastics production chain in the CIS and Eastern Europe, ranging from crude oil to advanced finished products (including parts and assemblies of the MC-21 modern passenger airliner and other aircraft, elements of spacecraft, ships made of composites, wind blades, etc.). It also has industrial facilities for the production of glass fibre, stone wool insulation, etc.

Today, the Composites Division is busy developing, implementing and qualifying a range of carbon fibre products at its plants located in Tatarstan and Saratov Region, using its own PAN precursor to replace the imported precursors in the aviation, rocket engineering and nuclear industries. The production of unique high-modulus carbon fibres, also based on domestically produced PAN precursors, is increasing in Chelyabinsk The composites’ recycling project is now also underway. There is an ongoing implementation of the Integrated R&D Programme aimed at innovative composite materials and their production so as to phase out imports and meet the needs of Russia’s key industrial sectors.

The carbon fibre production capacities set up by the Division together with rapid advancement of its own technologies have made it possible to fully replace foreign-made products. The strategic industries are supplied with 90% of advanced domestic fibres. Thanks to the Division’s efforts, Russia has become one of the leaders in the carbon fibre reinforced plastics segment.

Given the constantly growing industrial needs, the Division is faced with the task of ensuring the necessary technological reserves for scaling up production in Russia with domestically made equipment. This is why a robust engineering area of focus has been set up within the Division, and Russian partners have been identified to establish a joint venture for equipment prototyping.

The Composites Division has also acquired a glass fibre and fabrics plant in the Vladimir Region at the end of 2022, increasing its presence in the composites market. Today, the company produces about 55,000 tonnes of glass fibre, which accounts for 40 to 50% of the Russian market in this segment.

Applications of Composites

Currently, there are 29 companies and 16 production facilities in 15 Russian regions.

In 2023, carbon fibre and prepregs produced in-house enjoyed the highest demand among the Division’s product line-up. The aviation market shows the highest growth as the volume of carbon fibre supplies for the needs of Russian aviation has doubled compared to 2022. Space industry and shipbuilding are experiencing growth, too; there is also an increased market’s interest in composites related to sports gear, healthcare and industrial needs.

- Composite Solutions for Construction

As part of the project aimed at promotion of composites in construction, a number of production sites is being configured, which will expand the application of finished products made of composites. This includes plants specialising in structural composite products made through pultrusion with an annual output capacity of 2000+ tonnes.

The Division produces exterior reinforcement systems based on carbon fibre composite materials, which make it possible to compensate for engineering and construction errors and to reinforce buildings and structures during their renovation; sheet piles made of polymer composites used to set up retaining walls or to stabilise shorelines; floating modular structures to provide water-body crossing, and other temporary facilities in the water; thermal insulation materials.

- Composite Solutions for Natural Gas Vehicles

The Division produces highly reliable composite-to-metal cylinders for the storage and transport of compressed gases, to be installed on modern urban buses, municipal vehicles, long-haul tractors operating on methane as an environmentally friendly and cost-effective fuel. Moreover, a composite-to-metal cylinder designed for pressure up to 700 atmospheres was introduced in January 2024 to be used on hydrogen-powered vehicles. Among the Division’s clients are the largest Russian vehicle manufacturers — KAMAZ, MAZ, GAZ GROUP, VOLGABUS.

- Composite Solutions for Aerospace

The Division has played a major role in the success of the Russian MC-21 medium-haul aircraft project. For example, one of the most significant innovation products in today’s aviation industry is binder tape. This material is now made of domestically produced carbon fibre and used to automatically lay out the MC-21 wing. There are plans to develop a proprietary tape that will make the MC-21 wing even more advanced, improving its strength and aerodynamics.

Another promising area of focus is non-combustible prepregs, which are being developed at the Division’s research and production site in Moscow. They have a wide range of applications in aircraft interiors, floor panels, racks of avionics, and aircraft air-conditioning piping.

- Composite Solutions for Shipbuilding

A cooperation agreement was signed between the Composites Division, the Far East and Arctic Development Corporation, the Government of the Sakhalin Region and the Russian state development corporation VEB.RF at the Eastern Economic Forum in 2022. The agreement provides for the establishment of a shipyard in the port of Korsakov on Sakhalin Island for the construction of small-category sea boats made of composite materials.

To date, a project company has been registered on Sakhalin and an investment decision has been received from Rosatom. In late August 2023, a favourable decision from the VEB.RF Loan Committee was also received. The aim is to develop and establish the production of passenger, tourist and fishing boats made from composite materials.

- Composite Solutions for Sports

Acquisition of a stake in ZaryaD, Russia’s largest production site where hockey sticks of the same name are manufactured, has made it possible to set up the production of carbon fibre sticks produced by the Division in-house. Other sports products include motorbike components, professional carbon fibre SUP boards, etc.

- Composite Solutions for Wind Energy Industry

Plans have been laid out to launch the production of composite wind rotor blades in Ulyanovsk in late 2024, where blades weighing more than 7.5 tonnes and about 50 metres long will be manufactured. The scale of the production will provide the region with 400 new jobs and expand the Division’s line-up of composite products. The facility is designed to produce 450 blades per year. The key customer for the production of wind rotor blades is Rosatom’s Wind Power Division, with which a supply contract for several years has already been signed.