Lithium in the world

Today lithium is in the mainstream of the green economy; it is a critical element for the development of energy storage systems which have already been used on a large scale in a number of high-tech industries.

The world’s largest lithium producer is Australia (55%), followed by Chile (26%), China (14%) and Argentina (6%). The most significant lithium resources, which are concentrated in hydro-mineral sources (salars), are located in the countries of the “lithium triangle” in Latin America – Bolivia, Argentina and Chile.

Lithium in Bolivia

The development of lithium extraction in Bolivia will have a major impact on the global industry, since more than 21% of the world’s effective lithium reserves not yet involved in the economic turnover are concentrated in this country.

The basic strategic objective of the government of the Plurinational State of Bolivia at the moment is to develop a national policy for the industrialization of lithium, allowing the commercial extraction of lithium in Uyuni, Pastos Grandes, and Coipasa salt marshes in Potosí and Oruro departments, managed by YLB company (Yacimientos de Litio Bolivianos) and the Ministry of Hydrocarbons.

According to President Luis Arce, Bolivia aims to provide up to 40% of the world’s lithium supply by 2030, making it the “lithium capital of the world.”

International tender

An international tender for the direct extraction of lithium in Uyuni, Coipasa, and Pastos Grandes salt marshes was announced on April 30, 2021. The state-owned Yacimientos de Litio Bolivianos (YLB) was the tender operator.

The tender procedures included evaluating the performance and efficiency of technologies for the sorption extraction of lithium from the brines of Uyuni, Pastos Grandes, and Coipasa salt marshes with different content of lithium and impurities. Additional pilot tests demonstrated the sequence and conditions of the sorption extraction process, operation modes, and control algorithms.

For the evaluation, the bidders obtained a specific brine from each of Bolivia’s salt marshes. Trial tests of technologies of each company were held, and technical reports were submitted for the tender. The test results demonstrated the high competitiveness and efficiency of Russian technology.

The technical stage of the tender was completed on June 16, 2022. 6 companies, including Uranium One Group JSC (Russia), were shortlisted.

According to the President of the state-owned lithium company Yacimientos de Litio Bolivianos (YLB) Carlos Ramos, the best DLE technologies for salt marshes in Potosí and Oruro and proposals for organizing production were presented by four companies – Russian Uranium One, US Lilac Solutions, as well as Chinese CITIC Guoan and TBEA Group.

On January 20, 2023, YLB signed a framework agreement with the Chinese consortium CBC (which includes CATL, BRUNP and CMOC) to build an industrial complex for the production of lithium carbonate at the salars of Uyuni and Coipasa. Negotiations with other participants of the competition were continued.

Uranium One Group

Uranium One Group JSC, an organization of Rosatom, is one of the world’s major uranium mining companies with a diversified portfolio of international assets in Kazakhstan, Tanzania, and Namibia. Aiming at developing the mineral resource base abroad, Uranium One also implements promising non-uranium projects, including in the field of non-ferrous and rare metals. Lithium extraction is one of the most promising areas.

The company has advanced technologies and necessary expertise for a highly efficient extraction of lithium from brines and production of lithium products. To implement projects for the development of the national lithium industry, Uranium One Group relies on the best engineering solutions and production expertise of Rosatom’s organizations and know-how of leading Russian industrial companies.

The company’s long-term goal is to assist the Plurinational State of Bolivia to create a complete value-added chain of commercial applications of lithium in the country, from its efficient and environmentally friendly extraction in Bolivia’s salars to the manufacture of finished marketable and consumer demanded items: energy storage systems, etc.

About the project

For Rosatom, this is the first large-scale foreign project in the field of lithium production, with investments of up to 600 million dollars. Pastos Grandes salar, where an industrial complex is planned to be built, is at an altitude of 4600 meters above sea level. The planned starting production capacity of the enterprise is 25 thousand tons; it can be increased based on additional exploration of the resource base. The commissioning of the first phase and the start of production of finished products is scheduled for 2024.

Construction of the industrial complex for the production of lithium carbonate involves creation of the necessary infrastructure, including supply of water, electricity, and gas to the enterprise.

The project involves the best practices in energy efficiency, resource-saving technologies, and the use of renewable energy sources, all of which will result in an environmentally friendly product – “green” lithium.

Advanced production using the most efficient lithium extraction technology will not only increase state revenues, but also become the basis for the social and economic development of the region, contribute to the expansion of transport and energy infrastructure, the formation of related businesses, the training of national personnel, the development of the tourist potential of nature and culture of the Bolivian Altiplano, and, ultimately, improve the living standards in Bolivia.

Meeting the global trends, Rosatom nowadays is working to create a complete technological chain for the production of lithium products – from production both domestically and in foreign countries, to the production of the final product demanded by the market and consumers: electric vehicles, energy storage systems, batteries, as well as the creation of a network of filling stations for electric vehicles.

Characteristics of the Russian technology

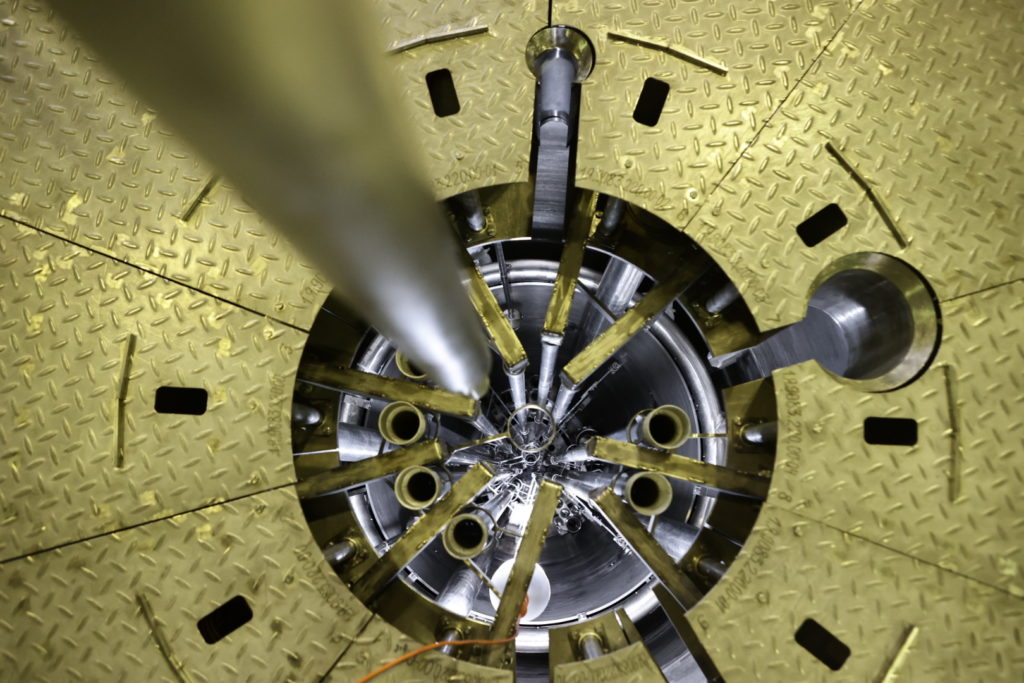

In the course of evaluation and pilot tests carried out by participating companies, Uranium One stood out with its Russian lithium sorption technology, achieving highly competitive and efficient results.

The Russian technology of sorption extraction of lithium from hydro-mineral media (salars) demonstrates a lithium extraction rate of about 90%. A distinctive feature of the Russian technology is a sorbent that showed an advantage in some key parameters compared to others. The technology does not depend on climatic conditions, the process is fully automated.

Environmental advantages of the Russian technology of lithium sorption extraction:

- no aggressive chemical acids are required (fresh water is used for lithium desorption);

- spent (after lithium extraction) brine returned to the salar has a chemical composition substantially similar to that of the original natural brine and is not harmful to the ecosystem;

- consumption of fresh water from external (underground) sources is no more than 20% of the total water consumption of the process, which is achieved by recycling water and does not damage the overall water balance of the salar and adjacent areas.

Rosatom in Bolivia

Rosatom has consistently developed the cooperation with Bolivia. In particular, the project for the construction of the Center for Nuclear Technology Research and Development (CNTRD) in El Alto, which is unique in Latin America, is being successfully implemented, offering Bolivia great opportunities for the application of nuclear technology in health, agriculture, and other sectors. The first radiopharmaceuticals produced at the cyclotron complex built by Rosatom have already been delivered to Bolivian clinics. The preclinical cyclotron and radiopharmacology complex (PCRC) will make it possible to completely replace the import of radiopharmaceuticals for the needs of nuclear medicine in Bolivia and will provide clinical trials for more than 5000 patients a year.

Lithium industry in Bolivia

According to the United States Geological Survey (USGS), Bolivia’s lithium resources are currently estimated at 21 million tons, or 21.4% of the world’s lithium resources. At the same time, lithium mining on an industrial scale in Bolivia is currently not carried out. To solve this problem, the Government of Bolivia has formed a program that provides for the involvement of foreign partners to participate in the industrialization of the lithium industry in Bolivia. As part of the implementation of the program, the authorized state company YLB held a competition among foreign participants who declared their technological solutions for use on the salars of Bolivia. As a result, partners were selected for the construction of industrial complexes for the extraction and production of lithium carbonate in the Bolivian salars of Uyuni, Coipasa and Pastos Grandes. The launch of lithium production is planned for the end of 2024.

Lithium industry in Russia

More than 80 years have passed since the first lithium mine was put into operation in Russia (then the USSR). Nowadays, with the help of Rosatom State Corporation, the country has created the production of a number of high-tech products based on white metal.

Novosibirsk Chemical Concentrates Plant (NCCP PJSC) is the only manufacturer of granulated lithium chloride in Russia and one of the two global manufacturers of products based on the lithium-7 isotope. In Russia, the Novosibirsk enterprise of Rosatom is the largest producer of high-purity metallic lithium. These products are supplied to consumers in the Russian Federation and exported to countries in Europe and the Asia-Pacific region.

Lithium metal is used in the production of lithium-ion batteries and cells, pharmaceuticals, chemical industry, etc. Besides, the lithium-7 isotope is used in the nuclear industry.

In Russia, at the state level, a task has been formulated for the large-scale development of ”green” energy – the development of carbon-free energy sources and storage systems and the expansion of opportunities associated with their use.

In accordance with the Concept for the Development of Electric Transport, approved by the Government of the Russian Federation, it is planned to produce at least 217,000 electric vehicles in 2030. To this end, a complete chain of industrial cooperation is being created in the country from the extraction of lithium raw materials to the production of lithium-ion batteries for electric vehicles and stationary energy storage systems. The main role here is played by Rosatom, which is already engaged in the processing of lithium, the production of metallic lithium and lithium-7 isotope. It is implementing a large-scale program in the Russian Federation to create the production of energy storage systems that are in demand by manufacturers of domestic electric vehicles and electric buses. Raw material supply for plans of the development of lithium-based energy storage systems for electric vehicles is planned through the use of domestic lithium raw materials and its supplies from abroad. The new production facility in Bolivia will solve this problem. Besides, participation in the project will provide Rosatom with a share in the dynamically developing world market.

The production of lithium-based energy storage systems for special equipment, telecommunication networks, uninterruptible and emergency power supplies and other areas is carried out by RENERA, an industry-specific integrator of Rosatom.

Even today, Rosatom is building the first ”giga-factory” in the country (in Kaliningrad region) for production of transport energy storage systems. There, in 2025, the full-scale production of reliable, safe and powerful lithium-ion storage batteries for electric vehicles. The production capacity will be 4 GW · h/year, that enables to provide up to 50 thousand electric vehicles with lithium-ion batteries per year. New production will allow to switch to more environment friendly transport, to ensure noise level reduction and air pollution reduction in big cities.

Rosatom’s lithium-ion batteries are used in trolleybuses with increased autonomous running, which operate in Saint Petersburg; tourist electrocars are available in the Moscow Region; and the future Russian electric car will be equipped with the Rosatom’s battery with the drive range of 500 km, which is equivalent to the world analogues.

A joint venture between ARMZ JSC (Rosatom Mining Division) and MMC Norilsk Nickel PJSC – Polar Lithium LLC – has launched a project to develop the lithium resource base of the Kolmozerskoye deposit in the Murmansk Region, one of the largest deposits in the world. Plans for the development of the Kolmozerskoye deposit provide for the extraction and production of 45,000 tons per year of lithium carbonate.

Rosatom has also launched the production of lithium hydroxide using its own unique technology in Angarsk in 2021 in a pilot mode. The launch of industrial production is scheduled for 2027.