Additive technologies (additive manufacturing) – also known as 3D printing – mean a method of making 3D objects, parts or items by laying down layers of material. Such three-dimensional objects are created with 3D printers.

The main advantages of additive technologies include reduced production time and cost, production of uniquely shaped items (impossible to be produced by any other means), the possibility of quickly producing single samples (especially important in the case of maintenance and repairs), small-scale production, and production of any parts at remotely located sites.

The combination of additive technologies and modern digital tools allows for so-called “reverse engineering”, that is, the creation of a part by analogy with an existing sample.

Another advantage of additive technologies is customization. For example, medicine uses 3D printed implants customized to fit each patient’s unique anatomy.

In recent years, additive technologies have been used in a variety of fields ranging from the automotive sector to the aerospace industry. Additive technologies make it possible to minimize production costs, create more complex parts, and reduce the production time of a part. In contrast to conventional methods, additive technologies allow for producing uniquely shaped items without seams or joints.

Rosatom is the first of the major Russian industrial companies to begin developing technologies and manufacturing domestic 3D printers.

In recent years, Rosatom has created a complete production chain including 3D printers manufacturing, software development, metal powders production, and 3D printing services. The nuclear industry is both a supplier of and a major customer for additive manufacturing technologies, actively introducing them into its business processes. Rosatom is developing a regional network of additive technology centers. Thus, Rosatom contributes to the government goals of strengthening national technological sovereignty.

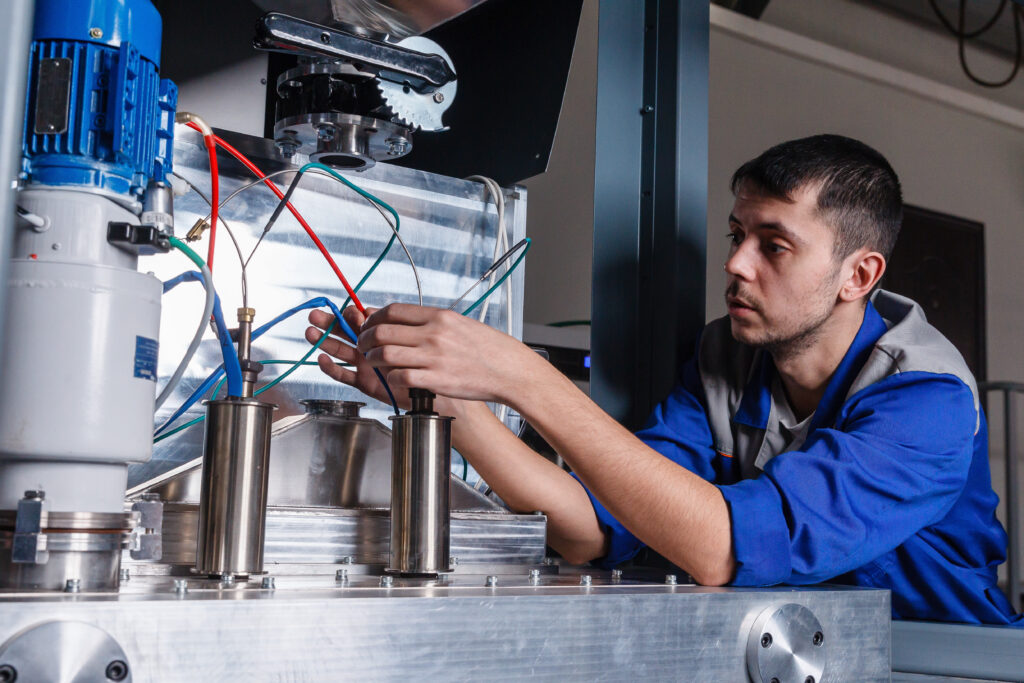

The additive technologies integrator company in the nuclear industry (belongs to Rosatom Fuel Division) comprises scientific and manufacturing assets of Rosatom as part of the development of domestic additive technologies. The integrator operates with the focus on four key areas including production of a range of 3D printers and their components, creation of 3D printing materials and metal powders, development of comprehensive software for additive systems, as well as 3D printing services and introduction of additive technologies in manufacturing (including organization of production centers). The end users receive the equipment or parts they need, production is faster than in the case of conventional welding and casting.

At present, at least 15 industry companies have in-house 3D printers using various technologies. Six of these companies have industry Additive Technology Centers (ATCs) that are engaged with elaboration of stainless steel and titanium alloy printing using the selective laser melting (SLM), fulfillment of commercial orders for 3D printing, modification of machines and scientific and technical research.

In addition, in May 2023, the additive technology Integrator Company presented the largest made in Russian 3D printer using direct metal deposition technology (DMD). This 3D printer is capable of printing items with a maximum diameter of 2.2 m and a height of 1 m, which could not be achieved with an additive method before. The innovative 3D printer can be used in all key high-tech industries including nuclear industry, aviation, shipbuilding, and space. The DMD method used at the metal-working facilities in the nuclear industry will make it possible to reduce the cost and production time of large-sized products, as well as to proceed to the development of new promising designs.

The company also made Russia’s first dual-laser and dual-powder printer while also being engaged with the development of new materials for 3D printers. The commercial 3D printer using metal powder compositions has gone into mass production. RusMelt 310M is the first Russian mass produced commercial 3D printer using selective laser melting method. Rosatom companies assemble printers in batches, the first one including nine machines, which will cover almost a third of the total industry needs in 2024.

Thanks to Rosatom, additive technologies are being introduced into the most complex and knowledge-intensive industries: the nuclear industry, aerospace industry, medicine, automotive industry and many others. Additive technologies allow for reduced costs and production time of products as well as ensured high level of customization. The Moscow Center for Additive Technologies demonstrates the capabilities of additive technologies available in the nuclear industry in full scope.

Rosatom Fuel Company TVEL (Rosatom Fuel Division) includes companies engaged with nuclear fuel fabrication, uranium conversion and enrichment, production of gas centrifuges, as well as research and design activities. As the only nuclear fuel supplier for Russian NPPs, TVEL supplies fuel for a total of more than 70 power reactors in 15 countries, research reactors in nine countries, and propulsion reactors of the Russian nuclear fleet. Every sixth reactor in the world runs on TVEL fuel. Rosatom’s Fuel Division is the world’s major producer of enriched uranium, being the leader on the global market for stable isotopes. The Fuel Division is actively developing new businesses in chemistry, metallurgy, energy storage technologies, 3D printing, digital products, and decommissioning of nuclear facilities. TVEL also includes the industry integrators for additive technologies and electricity storage systems of Rosatom.