Specialists of the Shared Access Additive Technology Center (SADTC), which was created with the support of Rosatom on the basis of Tomsk Polytechnic University, designed and 3D-printed the first lot of tooling for the manufacture of complex components of medical equipment, e.i. urological extractor baskets.

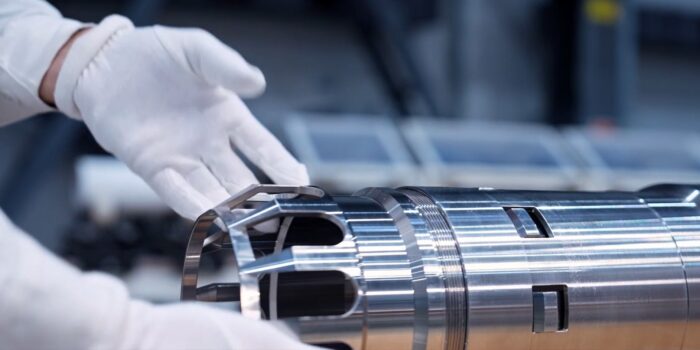

Urological extractors are actively used in the treatment of urolithiasis and cholelithiasis to capture and extract stones. The tooling is used to make the trap basket, the part of the extractor that is used to capture and extract the stone. Tooling for the manufacture of urological extractor baskets must have certain characteristics: not to oxidize when heated up to 500 degrees, have low heat capacity, withstand repeated cycles of heating and cooling.

The use of 3D printing has made it possible to produce high-quality tooling much faster, unlike traditional methods that require the use of fine turning and milling. If using the traditional method, each part is made separately, and the process takes about two to three hours. Whereas 3D printing can produce a lot of 150 toolings in 24 hours. In addition, using a printer makes the process more economical; the cost per part is reduced by about half when compared to traditional methods.

The first lot of tooling has been printed from nickel-based metal powder on the RusMelt 300M printer which is manufactured at the Rosatom's Fuel Division enterprises and makes it possible to create complex parts with high precision using selective laser melting (SLM) technology. The 3D printer build area is 300x300x370 mm. The capacity is up to 35 cubic centimeters per hour. RusMelt 300M provides high quality printed products combined with ease of operation and maintenance. The products went to medical institutions in Omsk, Perm, Kaluga, Nizhny Novgorod, Nadym and other cities.

“To our knowledge, this is the first time a heat-resistant alloy 3D printer has been used to create such tooling. So it was a definite challenge for the SADTC team. The engineering task was successfully solved, we received feedback from the customer, worked out heat-resistant alloy printing modes, tested the printer and made sure of its high technical characteristics,” Evgeny Bolbasov, Head of the Tomsk Polytechnic's SADTC said.

“Rosatom is addressing the issue of 3D printing accessibility in the regions by developing a federal network of Shared Access Additive Technology Centers. On the example of SADTC in Tomsk Polytechnic University, we see a successful collaboration between the university, the Tomsk region enterprise and Rosatom State Corporation, which has improved the quality and functionality of the product, increased production efficiency due to its flexibility and high-speed implementation of the most ambitious engineering tasks,” Ilya Kavelashvili, Director of the Additive Technologies of Rosatom's Fuel Division said.

Fuel Division of Rosatom State Corporation (JSC TVEL asset management company) incorporates enterprises specializing in nuclear fuel fabrication, uranium conversion and enrichment, production of gas centrifuge machines, as well as R&D organizations. TVEL is the sole supplier of nuclear fuel for Russian NPPs and supplies fuel to more than 70 power reactors in 15 countries, research reactors in nine countries, as well as transport reactors of the Russian nuclear fleet. Every sixth power reactor in the world is powered by fuel produced by TVEL. The Fuel Division is the largest global manufacturer of enriched uranium and a major player in the global market of stable isotopes. The Division is actively developing new business lines in the fields of chemistry, metallurgy, energy storage technologies, 3D printing, digital products, as well as decommissioning of nuclear facilities. Rosatom Sectoral Integrators for additive technologies and energy storage systems have been established. www.tvel.ru

The Additive Technologies of Rosatom State Corporation combines the full production cycle from the development of 3D printers and components to special powders, software, production of materials for printing and training. The company provides Russian manufacturing enterprises of strategic industries with innovative and reliable equipment, materials and professional service for the implementation of additive manufacturing technologies. https://rosat.tvel.ru