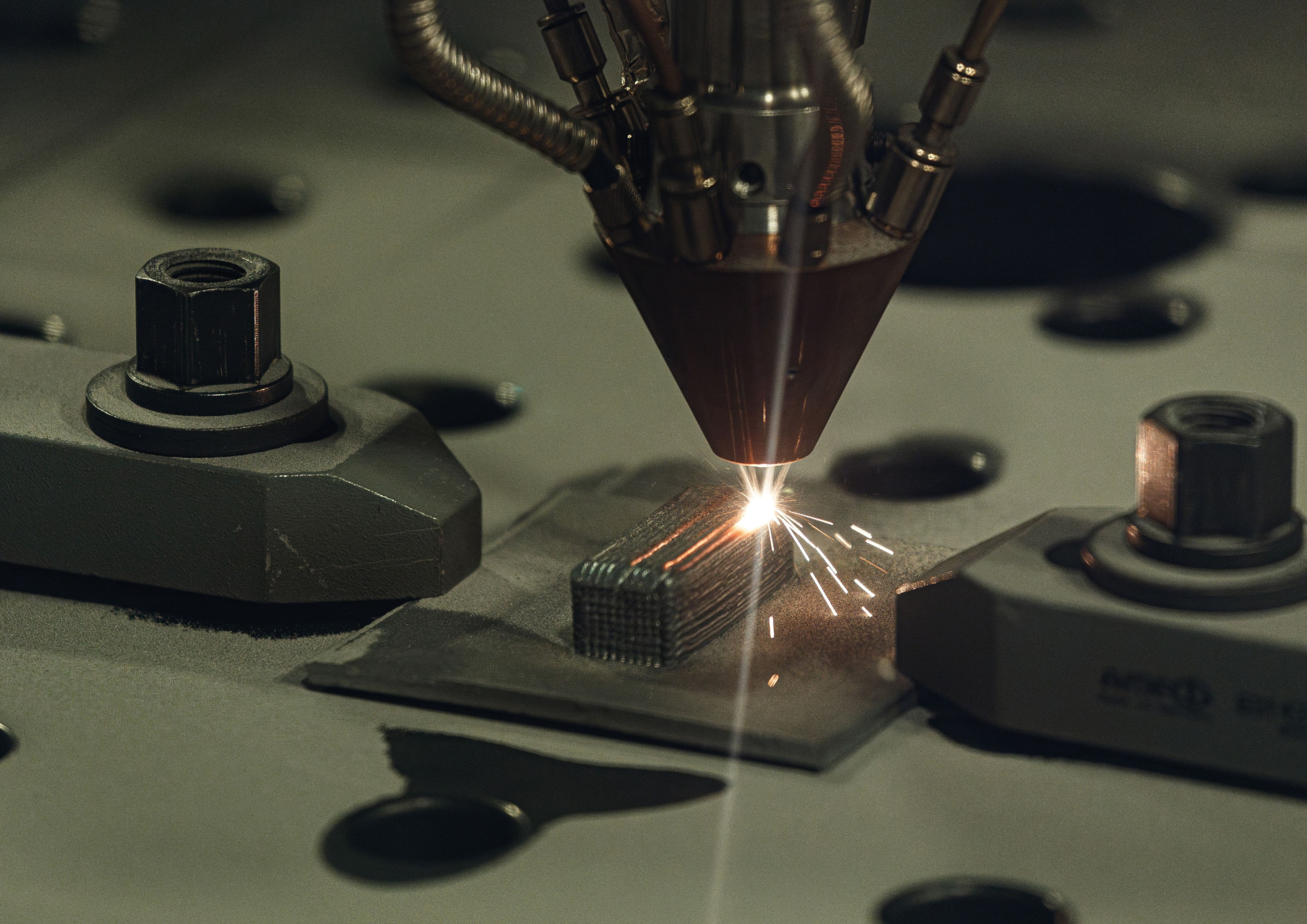

I. I. Afrikantov Experimental Design Bureau of Mechanical Engineering, the Mechanical Engineering Division of Rosatom, has received permission to manufacture equipment elements for the RITM-200 reactor plant using a domestic 3D printer. The first element manufactured with the help of additive technologies was a component of pumping equipment in a nuclear power plant — a terminal box.

The prototypes underwent a full range of studies in accordance with the program and test methodology agreed with the parent materials science organization and confirmed the possibility of using the 3D printing method in the manufacture of elements of the RITM-200 ship reactor plant. To date, regulatory documentation has been developed and approved, and the first Russian certificate of the Russian Maritime Register of Shipping has been obtained. The realization of this project made it possible to gain experience in manufacturing reactor equipment elements using additive technologies, to develop regulatory documentation in this direction and to further manufacture more complex and responsible products for RITM-200 on a 3D printer.

"Obtaining regulatory documentation for the first element for the RITM-200 reactor plant manufactured with the use of additive technologies makes it possible to replicate 3D printing technology in the future to create various equipment for marine nuclear power plants, as well as nuclear industry equipment of other types and purposes," said Yuri Vytnov, Chief Technologist of Afrikantov OKBM.

"The use of additive technologies in the production of elements for RITM-200 demonstrates the high level of technological readiness of the Russian industry. The use of 3D printing opens up new opportunities for design and production. It is possible to create parts with optimized geometry and improved characteristics. This makes it possible to increase the efficiency and reliability of equipment, as well as reduce its weight and cost," said Ilya Kavelashvili, Director of the Additive Technologies business area of Rosatom's Fuel Division.

This is the first time that elements of reactor units have been manufactured on a 3D printer in the Russian nuclear industry. Previously, this technology was used to create parts for bench equipment, process tooling and prototype models. The use of additive technologies in industry makes it possible to increase the service life of products, increase economic efficiency and reduce labor costs.

A pumping equipment element for RITM-200 was printed on an Ilist-L+ 3D printer

developed and manufactured by Rosatom in partnership with the St. Petersburg

State Marine Technical University. The elements were produced in Rosatom's

Nizhny Novgorod center for additive technologies at the Afrikantov OKBM site,

which was established in 2023 with the participation of the Additive

Technologies business unit of Rosatom's Fuel Division.

The RITM-200 reactor unit was created taking into account more than 60

years of experience in the operation of nuclear-powered vessels combined with

the use of all modern achievements in 3D design, calculation programs and

supercomputers. RITM-200 has a unique combination of high power, safety and

compactness, which determined the most important indicator of a universal

nuclear icebreaker — variable draft. This means versatility, reliability,

safety, environmental friendliness and economic efficiency. In addition to the

lead nuclear icebreaker of Project 22220 Arktika, serial icebreakers Sibir, Ural

and Yakutia are already in operation in the Russian nuclear icebreaker fleet,

with Chukotka, Leningrad and Stalingrad under construction, last one launched

on November 18. The RITM-200 reactor units, which proved their efficiency in

the conditions of the Far North, became the basis for energy solutions —

floating power units and low-capacity nuclear power plants capable of supplying

electricity to remote areas in the country and abroad. As a result, a series of

floating power units are being built to supply power to a large industrial

consumer in Chukotka; a project to build an SNPP with RITM-200 in Yakutia and

Uzbekistan is underway.

The Mechanical Engineering Division of Rosatom State Corporation is

Russia's largest power engineering holding in terms of production volume and

revenue. It supplies a comprehensive range of equipment for reactor and turbine

islands of all Russian-designed NPPs; designs manufactures, and delivers

integrated solutions for the power, oil and gas, and other industries.

The Fuel Division of Rosatom State Corporation includes enterprises that

fabricate nuclear fuel, convert and enrich uranium, produce gas centrifuges, as

well as research and development organizations. As the sole supplier of nuclear

fuel for Russian NPPs, the division provides fuel for a total of more than 70

power reactors in 15 countries, research reactors in nine countries, and

transport reactors of the Russian nuclear fleet. Every sixth power reactor in

the world runs on the division's fuel. Rosatom's Fuel Division is the world's

largest producer of enriched uranium, as well as the leader in the global

market for stable isotopes. The Division is actively developing new business

lines in the fields of chemistry, metallurgy, energy storage technologies, 3D

printing, digital products, as well as decommissioning of nuclear facilities.

Industry integrators for additive technologies and energy storage systems have

been created as a part of the Rosatom fuel company.

The Additive Technologies business area combines the full production cycle,

from the development of 3D printers and components to specialty powders,

software and personnel training. The company provides Russian manufacturing

enterprises in strategic industries with innovative and reliable equipment,

materials and professional service for the implementation of additive

manufacturing technologies.

By developing 3D printing technologies and a regional network of additive manufacturing centers, Rosatom contributes to the solution of government tasks in strengthening technological sovereignty. Widespread use of 3D-printing technologies will help reduce production time and cost by several times, and will help overcome barriers in the area of import substitution.