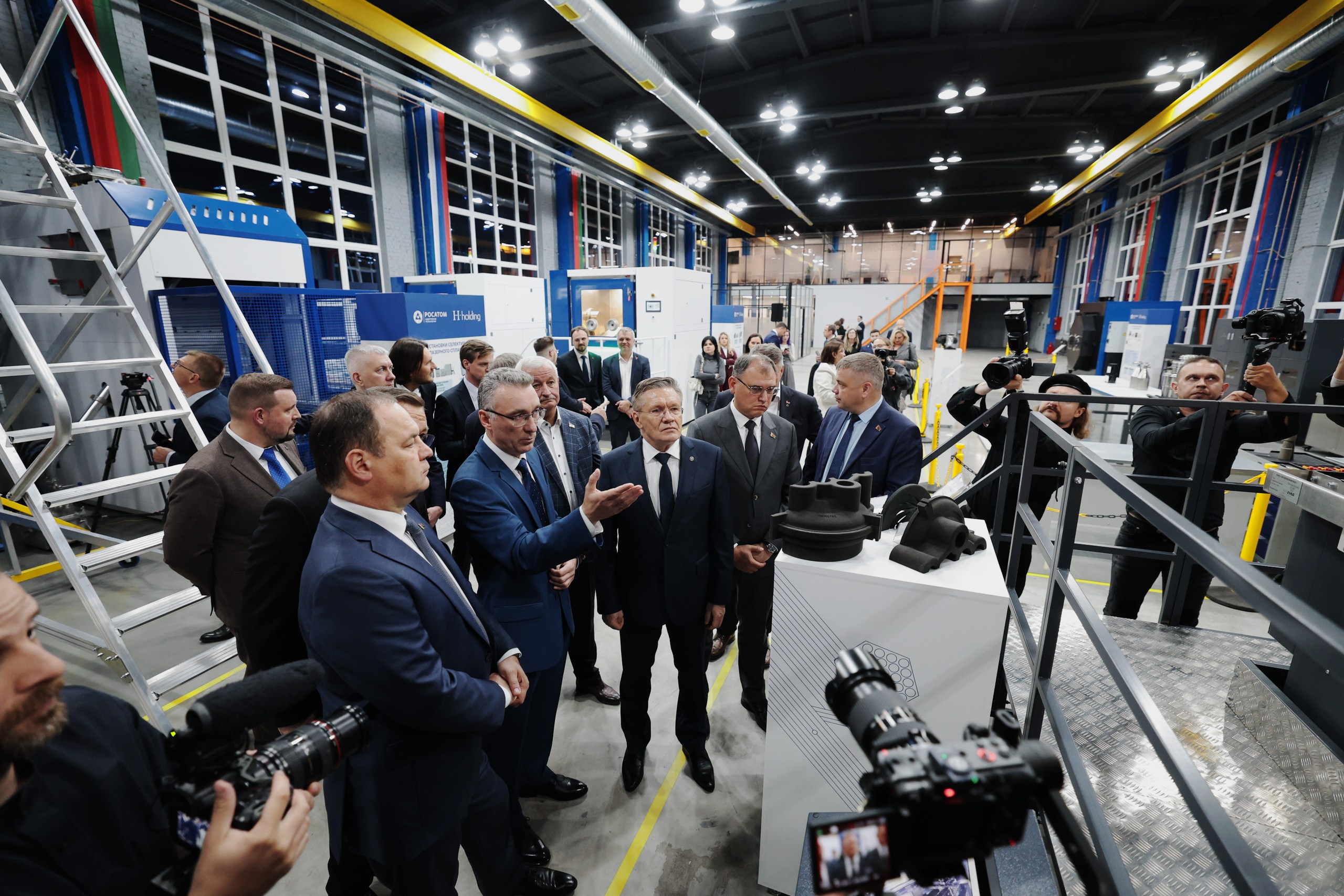

Rosatom opened the first Additive Technologies Center (ATC) in the Republic of Belarus, timed to the INNOPROM.Belarus international exhibition. The project was implemented as a joint venture of Rosatom and the Belarusian company H-Holding.

"With the support of the President of the Republic of Belarus, cooperation between the Government and Rosatom is developing dynamically in many areas. The opening of the Additive Technologies Center is the first vivid example of the innovative non-nuclear project implementation. Belarusian enterprises are already switching to the use of additive technologies, and the appearance of such a facility in the country will give a new impetus to the development of new types of products and their application in medicine, energy, aircraft construction and other high-tech industries," Viktor Karankevich, Deputy Prime Minister of the Republic of Belarus, said at the opening of the Additive Technologies Center.

"After the commissioning of the second power unit of the Belarusian NPP at the request of the President of the Republic of Belarus, we started working on new projects, including non-nuclear business areas, which grew out of our competencies in the nuclear industry. The introduction of additive manufacturing ensures the transition to a new technological paradigm. Compared to traditional production technologies, 3D printing allows us to produce unique products of complex shape with specified parameters quickly and cost effectively based on a zero waste principle. The creation of the Additive Technologies Center was the number one item on the roadmap of our cooperation with the Government of the Republic of Belarus, and this project was implemented ahead of schedule. All the equipment in this center is fully technologically independent from third countries, and more than half of the machines are manufactured by Rosatom. I am confident that the center’s export potential will soon allow it to enter foreign markets with its products and services," said Alexey Likhachev, Director General of Rosatom, during the ceremony.

This is Rosatom’s first Additive Technologies Center (ATC) created

abroad. It is based on the experience and expertise accumulated in the Russian

nuclear industry: since 2020, with the direct participation of the Additive

Technologies business of Rosatom's Fuel Division, three ATCs have been

established at Rosatom's enterprises. Seven more general access centers for

additive technologies have been opened at educational institutions in various

regions of Russia, from Belgorod to Khabarovsk. The Center is equipped with two

machines for metal printing using selective laser melting (SLM) technology.

These are medium-sized SLM-printer RusMelt 300M and large-sized RusMelt 600M -

both serial units were created by the nuclear industry specialists taking into

account the requirements of the customers - leading representatives of the

Russian industry. In addition, the ATC is equipped with a Russian made machine

for printing sand polymer molds for casting, as well as a 3D scanner developed

by Rosatom's technology partner. The possibility of 3D scanning in combination

with 3D printing enables a comprehensive approach — from manufacturing products

to the customer’s model to reverse engineering.

As part of Rosatom's exposition at the INNOPROM. Belarus a 3D-printed

component for the needs of the national Belarusian energy company, State

Production Association of Electric Power Industry "Belenergo" –

a pre-swirl impeller for a condensate pump was presented. Previously, such

components for CHP plants had to be imported.

The Belarusian Additive Technologies Center will be able to produce up to 1.5 tons of products from various metals, up to 3 tons of sand-polymer molds and up to 100 kg of engineering plastics products per year. Taking into account the nature of additive manufacturing (small and medium batch production of products of complex geometry and unique design), the production capacity of the ATC will allow to meet the growing demand for 3D printing technologies in key sectors of the Belarusian industry.

The ATC will also manufacture small printers for metal printing, which are in demand in the medical industry, scientific centers and educational institutions.

«With the support of the Government of the Republic of Belarus, Rosatom specialists traveled to more than 50 enterprises in the country to conduct a technological audit and assess the prospects for the introduction of 3D printing. Today, many giants of Belarusian industry are already using additive technologies and are considering printing products for their serial production. The Minsk Additive Technologies Center is a model example that we will demonstrate to partners from other countries who are considering similar projects. This facility should become a center of attraction for technically oriented young people. We will invite students here for internships and schoolchildren for early career guidance. In 10 years, this will give the country a generation of engineers and managers who will be able to use all the advantages of additive technologies," Ilya Kavelashvili, Director of the Additive Technologies business track of Rosatom's Fuel Division, said at the ceremony.

An important aspect of the center's work will be cooperation with H-Holding Group enterprises in post-processing of printed products, including finishing machining and application of specialized coatings that meet individual customer requirements.

Additive technologies make it possible to produce parts and components

that are difficult to manufacture by traditional methods using casting and

machining. 3D printing reduces the weight of products, optimizes the materials

used and shortens production time. Modern 3D printers allow you to quickly

reconfigure printing parameters to produce products from different materials.

3D printing products are used in a wide range of fields, from nuclear and space

technologies to medicine.

RN Additive Technologies Center LLC is a joint Russian-Belarusian

enterprise established to create the Republican Additive Technologies Center

within the framework of the Roadmap for Cooperation between Rosatom and the

Government of the Republic of Belarus (approved in December 2023). At the

initial stage in 2025, the CAT will provide 16 highly qualified jobs, and by

2027 it is planned to increase their number to 40.

H Holding is a Belarusian manufacturing group that includes 20 enterprises producing over 1,500 models of consumer electronics. The company employs 5,000 people. An important aspect of ATC’s work will be cooperation with the H Holding group’s enterprises in the post-processing of printed products, including final machining and the application of specialized coatings that meet customers’ individual requirements.

Rosatom state corporation was one of the first in Russia to start developing domestic 3D printing equipment. The Additive Technologies business track (as part of Rosatom's Fuel Division) provides a comprehensive solution from the development of 3D printers, components, printing materials, software, service support and personnel training to the provision of 3D printing services, as well as the creation of turnkey additive technologies centers at the customer's enterprise.

Rosatom integrates the entire cycle of additive manufacturing and supplies Russian manufacturing companies in strategic industries with innovative and reliable equipment, materials and professional service for the implementation of additive manufacturing technologies. The company provides a comprehensive offer for the introduction of additive technologies: printing using three different technologies: metals, polymers and sand, as well as 3D scanning, R&D, and technological audits to identify optimal implementation paths.