LUCH JSC (Rosatom’s Science division in Podolsk) has developed a pilot commercial technology for the production of fuel for high-temperature gas-cooled reactors (HTGC). The technology is based on production equipment developed and manufactured by Russian companies.

Reactor tests and laboratory studies of HTGR fuel samples have shown that the materials and selected design of the HTGR fuel ensure the containment for gaseous fission products generated during irradiation of nuclear fuel at temperatures up to 1600°C (this temperature may occur in the event of disruption in normal operation of the HTGR). Specialists from LUCH JSC developed the technological basis for the production of HTGR fuel. They selected technological modes for key production processes (using models and laboratory samples of high-performance equipment) and prepared technical specifications for the production line equipment. The pilot facility consists of four process sections and more than 20 pieces of one-of-a-kind equipment, which were specifically engineered and manufactured by Russian companies, including by those in the nuclear industry. In terms of its output (batch size) and equipment configuration, the pilot facility is similar to a production line within a future fuel facility. The site also has analytical equipment and facilities for quality control of HTGR fuel production, including a Russian X-ray tomography system for online monitoring of the uniform distribution of micro-fuel elements in fuel compacts.

By now, an import-independent pilot line for the production of the HTGR fuel with a design output of 250 thousand fuel compacts per year has been arranged at LUCH JSC. The launch and future commercial operation of the line will ensure fuel supply for the main power unit of a nuclear power engineering plant with HTGR, including the chemical processing part.

“The pilot commercial line for the production of the HTGR fuel provides a solid foundation for the future development and implementation of a project to construct a pilot nuclear power engineering plant with HTGR and chemical processing section. Additionally, the development and commercialization of domestic technologies for producing micro-fuel with multi-layer protective coatings (TRISO) offers prospects for utilizing this type of nuclear fuel in other innovative reactor designs with enhanced safety,” said Andrey Mokrushin, Head of the HTGR Fuel Development and Deputy Director General for Science at LUCH JSC.

The production of pilot batches of micro-fuel elements and fuel compacts is scheduled for 2025. Some of these will be used for reactor resource tests and post-reactor studies (as part of the HTGR fuel pilot commercial production).

Reference

Since 2021, a group of industry companies, led by LUCH JSC, on behalf of Rosatom Electric Power division has been developing the HTGR fuel and pilot commercial technology for the fuel production, and preparing the analytical and experimental justification for the same. This work is part of an investment project aimed at working out technological solutions for a nuclear power engineering plant with HTGR and a chemical processing section that will produce hydrogen-based products and ammonia.

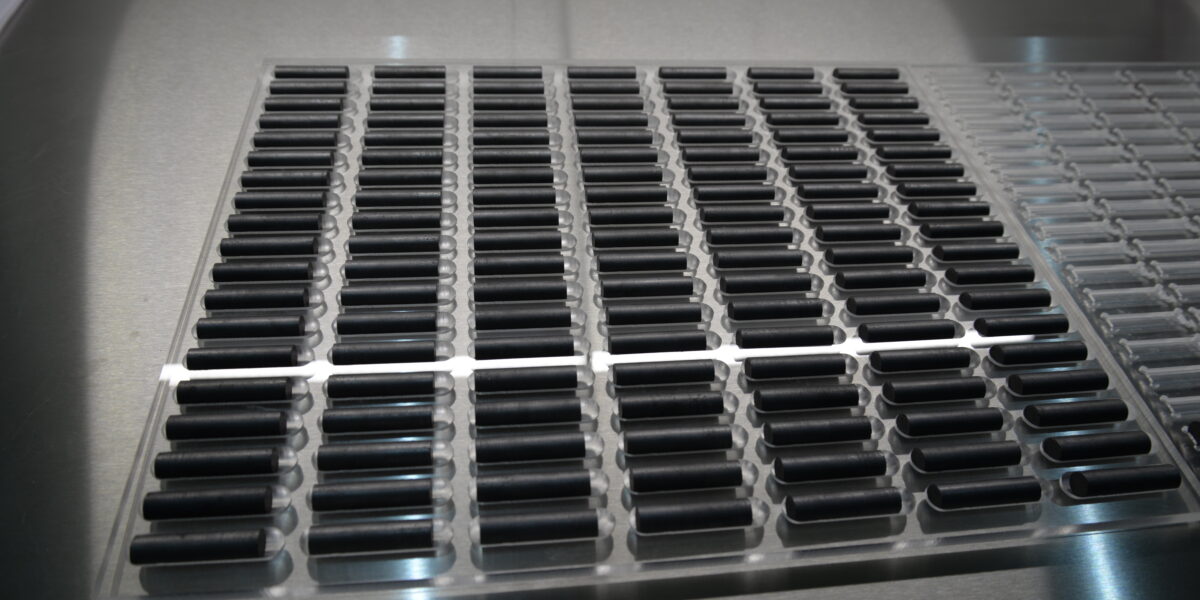

The HTGR fuel is made as microfuel elements consisting of spherical fuel kernels with a multilayer protective coating (TRI-structural isotopic particle fuel or TRISO fuel). These micro-fuel elements are placed in a graphite matrix and packed as cylindrical fuel compacts.

Hydrogen energy is one of the areas of Rosatom’s scientific and technological development. Rosatom is a technological leader in the global economy. It supports the global ecology agenda for low-carbon transition and implements a strategic program for hydrogen energy development in Russia. This program includes developing its own technological expertise throughout the hydrogen and hydrogen-based products supply chain, from promising methods of hydrogen production such as electrolysis, to its storage and transportation to local and foreign consumers. The largest companies within Rosatom are currently working on creating innovative and globally competitive solutions in this field, including cutting-edge electrolysis systems.

Rosatom’s Electric Power division is the major producer of clean energy in Russia. The division’s management company, Rosenergoatom, Joint-Stock Company, operates 11 nuclear power plants, including the world’s only floating nuclear power plant (FNPP). Thirty-six power units with a combined capacity of 28.5 gigawatts account for approximately 20% of the electricity generated in Russia. The division offers a comprehensive range of services, including commissioning, repair and maintenance, as well as training personnel of nuclear power plants. Additionally, the division’s companies produce isotopes for medical, agricultural, and microelectronic applications. The division is actively working in new areas such as the development of charging infrastructure for e-vehicles, biogas stations, and the manufacturing of industrial robots. rosenergoatom.ru

Since 2021, the Electric Power division has been running a large-scale investment project for the development of hydrogen energy technologies for the large-scale production and utilization of hydrogen and hydrogen-based products. The integrated project includes the work on technological solutions for creating a nuclear power engineering plant with HTGR (high temperature gas cooled reactor) and chemical processing section for the production of hydrogen-based products and ammonia (including the development of technologies for producing the HTGR fuel and for converting methane); design of a range of highly efficient electrolysis units, fuel elements, and hydrogen storage and transportation systems; as well as the studies to ensure supporting systems for safe operation of hydrogen energy facilities.

Rosatom’s Science division is engaged in innovative fundamental and applied research with a focus on developing both nuclear and non-nuclear technologies such as the closure of the nuclear fuel cycle, thermonuclear fusion, and nuclear medicine. The division also works on science-intensive technologies for both nuclear and other sectors. It consists of 13 research institutes and commercial companies including IPPE JSC, RIAR JSC, LUCH JSC, Giredmet, the V.G. Khlopin Radium Institute, and others. They possess a robust research infrastructure and in-house pilot production facilities, allowing them to implement a scientific idea from basic research to design development and prototype creation. The majority of the division’s scientific research and development efforts are taken within the context of the general industrial thematic plan. The scope of the division encompasses testing, development of high-tech medical equipment and innovative construction materials. It is running projects aimed at commercializing promising science-intensive technologies. https://niirosatom.ru/

LUCH JSC (Research and Production Association, Research and Development Institute, Joint-Stock Company) fulfils tasks related to the development of fuel elements and assemblies for nuclear power units and provides the nuclear industry with the same. The company also works on creating fuel compositions for new generation fuel elements. LUCH JSC is a manufacturer of advanced high-tech products based on monocrystalline and high-temperature materials. The company’s core technologies encompass the production of dense nuclear fuel, ceramic nuclear fuel, vacuum tubes and current sources, large laser optics and adaptive optical systems; processing of non-irradiated nuclear materials; development of I&C for nuclear facilities (resistance thermometers, thermocouples, flow meters, and level gauges, etc.), etc.

According to the IAEA’s classification, the fourth generation of nuclear power systems uses various technologies with common goals: to improve fuel efficiency, increase safety, enhance energy efficiency, and reduce spent nuclear fuel waste, etc. Gen IV nuclear power systems have the potential to transform the nuclear power fundamentally, primarily due to their increased safety, expanded fuel options, and substantially reduced radioactive waste. Russia is a pioneer in the development of Gen IV nuclear technologies. At the Beloyarsk NPP, preparatory work has commenced for the construction of a BN-1200M power unit. For the first time, a nuclear power plant with the BREST-OD-300 reactor and closed nuclear fuel cycle are being constructed on the same site in the Tomsk region.

Rosatom’s advanced technologies are based on outstanding achievements in Russian nuclear science. The effective cooperation between industrial facilities and research institutions fosters the national technological sovereignty, while also enhancing the competitiveness of the domestic nuclear sector.