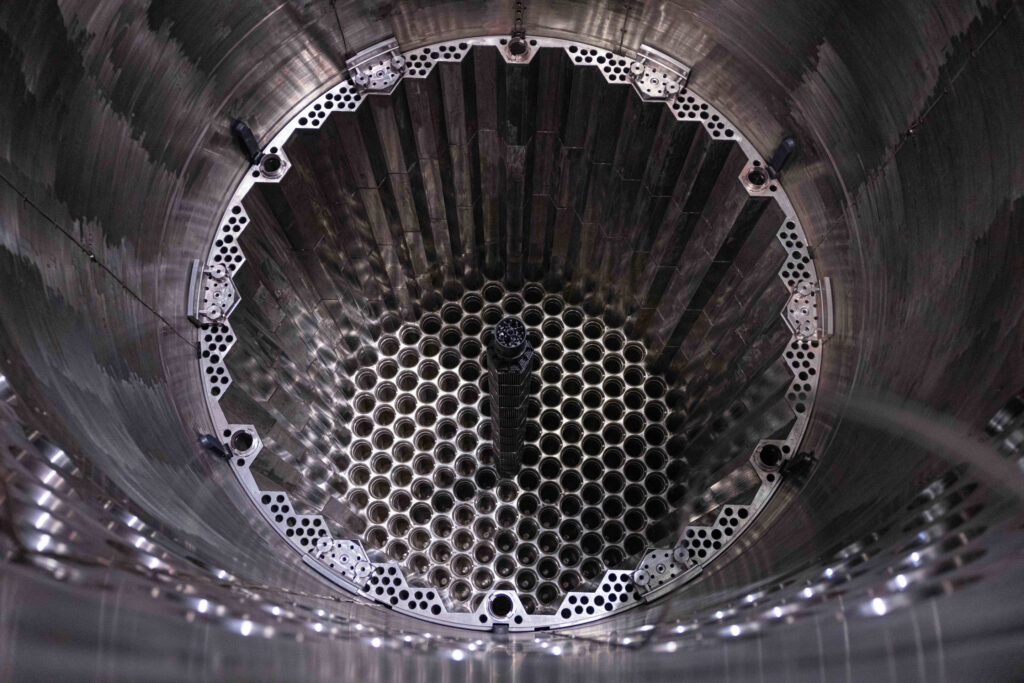

Loading of dummy fuel assemblies into the reactor pressure vessel has started at Unit 1 of the Rooppur NPP in the People’s Republic of Bangladesh (the general designer and general contractor is Rosatom’s Engineering Division). The work is performed by specialists of Atomstroyexport JSC, Atomtechenergo JSC and Rosenergoatom.

A dummy fuel assembly (DFA) is a piece of equipment fully imitating the design of standard fuel assemblies in terms of dimensions, weight and materials, but without nuclear fuel.

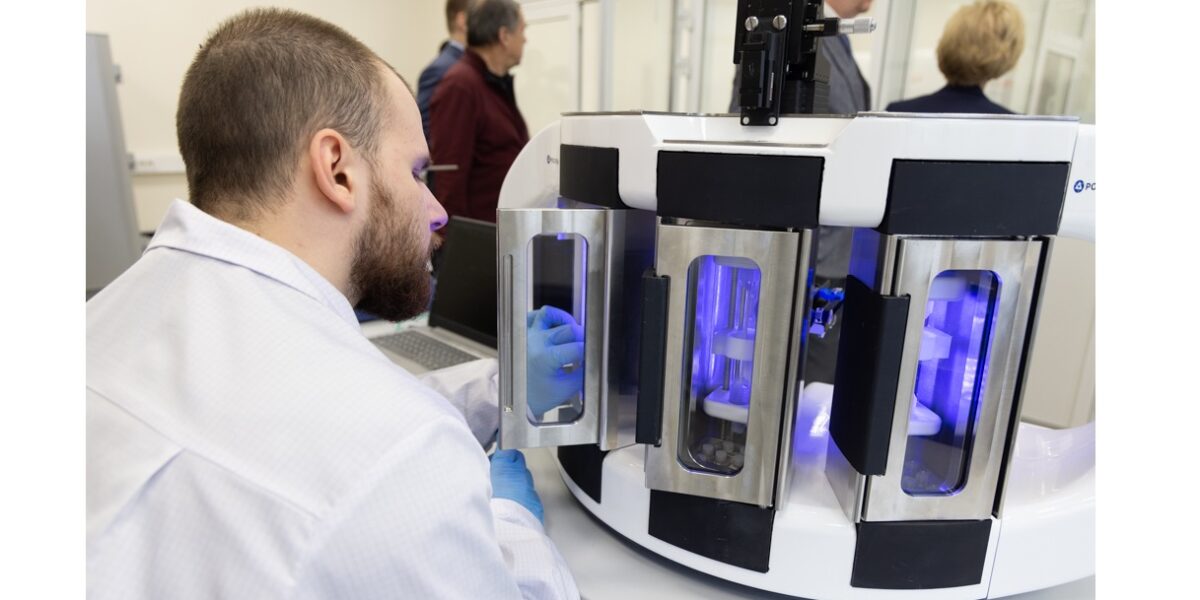

As part of the simulation area, they are designed to model the geometry of the reactor core and to confirm hydraulic parameters of the reactor plant during circulation flushing and reactor cold and hot tests. DFA are also necessary to master handling operations using the refueling machine. After confirmation of all parameters of the reactor plant with the aid of dummy assemblies, nuclear fuel loading will follow.

“Being the major technological corporation in Russia, Rosatom demonstrates every day its competencies and a successful experience in creating the conditions for development of new industries in its partner countries. Construction of Rooppur NPP is going on, the start-up and adjustment works at Unit 1 are in full swing. Upon the power plant start-up, Bangladesh will be provided with electricity for further development of the country,” noted Alexey Deriy, ASE JSC Vice President for Projects in Bangladesh.

According to Denis Muzlov, Director of Atomtechenergo JSC Branch in Bangladesh, all 163 DFA will be loaded over the next few days. “Work on the DFA loading will be performed 24/7. Loading of one DFA into the reactor, using the refueling machine in automatic mode, takes 25 minutes on average. After the DFA loading, we will start preparing the reactor for subsequent circulation flushing and cold and hot tests,” he commented.

The circulation flushing and reactor cold and hot tests are the most important step of start-up and adjustment works, preceding physical start-up of the power unit to confirm its reliable and safe operation.

Rooppur NPP equipped with two VVER-1200 reactors with the total capacity of 2,400 MW is being built according to the Russian design 160 km from Dhaka, the capital of Bangladesh, in compliance with the General Contract dated December 25, 2015. The Russian design with VVER-1200 reactors that had been successfully implemented at two units of Novovoronezh NPP was selected for the first NPP in Bangladesh. This is an evolutionary Generation III+ design which fully complies with all the international safety requirements.

Reference

The Rosatom State Corporation Engineering Division unites the leading companies of the nuclear industry, namely: Atomstroyexport JSC (Moscow, Nizhny Novgorod, branches in Russia and abroad), Joint Design Institute – Atomenergoproekt JSC (Moscow, Nizhny Novgorod, St. Petersburg branches – design institutes, branches in Russia and abroad, R&D branches) and subsidiary construction organizations.

The Engineering Division ranks first in the world by the order portfolio and the number of NPPs constructed simultaneously across the world. About 80% of the Division’s revenues originate from foreign projects.

The Engineering Division implements construction projects for high-power NPPs in Russia and across the world, renders a full range of EPC, EP, EPC(M) services including project management and design activities, and develops Multi-D technologies for the management of complex engineering facilities. The Division relies on the achievements of the Russian nuclear industry and innovative state-of-the-art technologies.

Russia is consistently developing international trade and economic relations, focusing on cooperation with friendly countries. Despite external restrictions, the domestic economy is augmenting its export potential to supply goods, services and raw materials all over the world.