During the scheduled refueling at the Beloyarsk NPP's Unit 4, its BN-800 fast neutron reactor has been for the first time loaded with lead-test assemblies of uranium-plutonium MOX fuel also containing the so-called minor actinides, the most radiotoxic and long-lived components from irradiated nuclear fuel.

The loading of innovative fuel into the reactor core was approved by Russia's authorized regulator Rostekhnadzor (the Federal Service for Environmental, Technological and Nuclear Supervision), which had confirmed its safe operation. The power unit has resumed operation after the refueling.

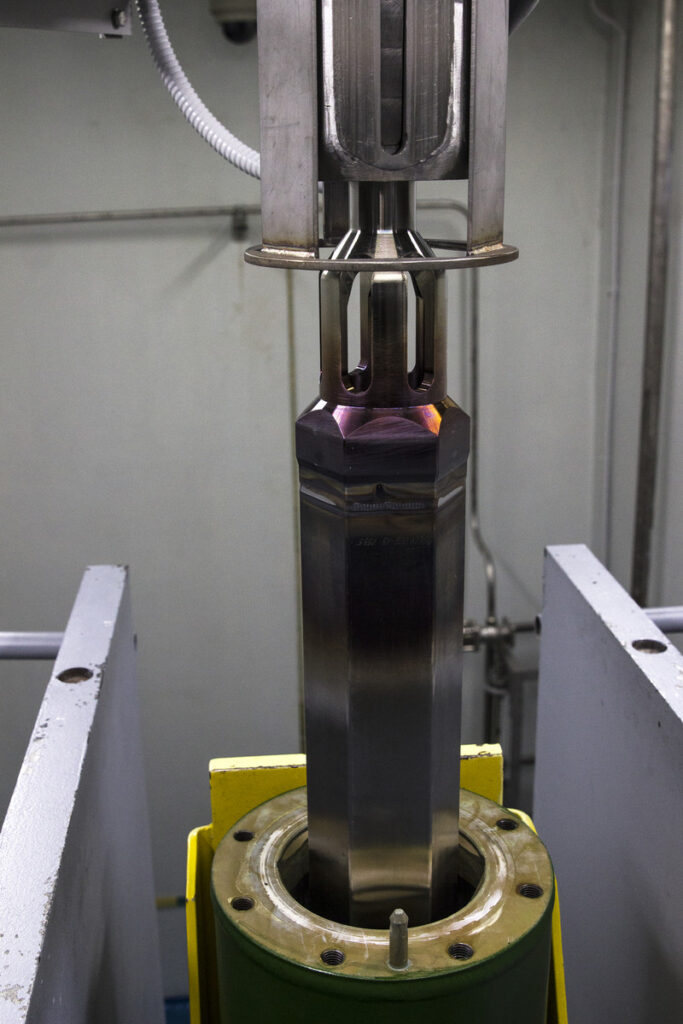

The three lead-test MOX bundles containing americium-241 and neptunium-237 were manufactured at Rosatom's Mining and Chemical Combine in late 2023. They will undergo pilot operation at the BN-800 core during three micro-campaigns (approximately a year and a half).

"The next micro-campaign of the BN-800 reactor should experimentally confirm the possibility of minor actinides utilization at industrial mode. The possibility to eliminate minor actinides is an advantage of fast neutron reactors, which allows reducing the volume of radioactive waste from the entire infrastructure of the nuclear fuel cycle of NPP operation," said Ivan Sidorov, Director of the Beloyarsk NPP.

According to scientists' estimates, afterburning of minor actinides in closed nuclear fuel cycle would enable the radiation equivalence of uranium feedstock and nuclear waste to be isolated in only 300 years, i.e. 2,300 times faster (about 700 thousand years in open nuclear fuel cycle).

The technology of MOX fuel fabrication, including the bundles with minor actinides, was developed by Rosatom's Fuel Division (managed by TVEL JSC). For the project of manufacturing the MOX bundles with minor actinides applying the common in-house technology and the regular industrial-scale equipment, Rosatom engineers had verified and validated 38 techniques for analytical control of the nuclear fuel properties.

"The bundles of MOX fuel with minor actinides, manufactured for a commercial large-scale fast reactor, are absolutely unique. This demonstrates the fundamental technological possibility to accomplish the most important component of generation-IV nuclear power systems. The service of minor actinides afterburning in nuclear fuel for fast reactors is a completely new product for the global nuclear industry. Uranium-plutonium fuel itself enables to expand the feed-stock base of the nuclear power industry, to recycle spent nuclear fuel instead of storing it, and to reduce the volume of nuclear waste. Further on, utilization of minor actinides is also an opportunity to significantly reduce radioactivity of the waste, which would enable in the future to abandon its complicated and expensive deep burial," said Alexander Ugryumov, Senior Vice President for Research and Development at TVEL JSC.

Russia is now the only country developing a complete Generation IV power system based on the closed nuclear fuel cycle technologies. In Seversk, West Siberia, Rosatom is building the Pilot Demonstration Energy Complex, including the power unit with the BREST-OD-300 fast reactor, the unit for nuclear fuel fabrication/refabrication, and the unit for irradiated fuel recycling.

Fast neutron reactors can be fueled not only by enriched uranium, but also secondary products of the nuclear fuel cycle, such as depleted uranium and plutonium extracted from spent nuclear fuel. The so-called afterburning of minor actinides in a fast reactor is the next step of the Russian nuclear industry in closing the nuclear fuel cycle. Under the fluence of fast neutrons, they will be divided into elements that pose a much lower potential danger.

Today, the Beloyarsk NPP is testing the elements of the future technology, as the new higher capacity fast reactor is being designed.

"Based on the experience of the unique power units operation at Beloyarsk NPP powered by the BN-600 and the BN-800 fast reactors, today a serial power unit with a fast reactor is under development. The first such unit with the BN-1200M reactor will be built at the Beloyarsk NPP as well. The new technological solutions would enable us to fully utilize the energy potential of uranium feed-stock, and also have a new level of safety," commented Alexander Shutikov, Director General of Rosenergoatom (Rosatom's Power Division).

Reference

Minor actinides are elements formed in uranium nuclear fuel (in addition to plutonium) during operation in any reactor. Neptunium, americium, and curium isotopes are especially important, since they make it especially complicated to reproces irradiated nuclear fuel and manage radioactive waste. These elements are highly radioactive and toxic, emit much heat, have a long half-life and are the most dangerous components of nuclear waste. All this requires special conditions for transportation, storage and final isolation.

Minor actinides management

Conventional nuclear industry is aimed at long-term storage and final disposal of spent nuclear fuel reprocessing waste without recovery of minor actinides. This method requires guaranteed safety of facilities for about a million years and significant disposal costs. Practices of deep geological disposal have not yet been fully implemented anywhere in the world. Mixing minor actinides into the fuel of fast reactors will enable to burn americium and neptunium, to reduce the volume of waste subject to deep disposal by several times, and in the future to switch to near-surface disposal of waste.

MOX fuel for fast reactors

Distinct from traditional nuclear fuel with enriched uranium, MOX fuel pellets are based on the mix of nuclear fuel cycle derivatives, such as oxide of plutonium bred in commercial reactors, and oxide of depleted uranium which comes from de-fluorination of depleted uranium hexafluoride (UF6), the so-called secondary tailings of uranium enrichment facilities.

The first serial batch of MOX fuel was loaded in the BN-800 core in January, 2020. A year later, the facility underwent the first full MOX refueling. Later, after the next two full MOX refuelings, all the uranium fuel bundles were replaced with the innovative MOX fuel.

Thermal neutron reactors, which make-up the core of the modern nuclear power industry, use about 1% of natural uranium, the remaining 99% is in fact sent for temporary storage or disposed as radioactive waste. Fast reactors, using a mixture of uranium and plutonium oxides as fuel, produce enough plutonium to support the development of the nuclear power industry.

Balanced nuclear fuel cycle (NFC) is a complex product of Rosatom. It is based on innovative practical solutions for closing the nuclear fuel cycle, which enable for efficient reprocessing of irradiated nuclear fuel and ensure rational management of products after processing, both useful (uranium and plutonium) and disposed (fission products).

Balanced NFC is mainly aimed at principal reduction of the volume and effect of radioactive disposed waste.

Balanced NFC:

- improves the safety of nuclear waste management and reduces environmental risks;

- addresses the problem of future generations and gives a pattern for sustainable consumption and production;

- reduces the volume and level of hazard of disposed waste to a minimum;

- reuses valuable raw materials in the NFC, i.e. recycles nuclear materials.